2016

CSEM designs for ESO the mechanism for the stabilization unit of the E-ELT M5 Mirror

The Swiss research and technology organisation CSEM has designed an adaptive optics control system for the ESO E-ELT telescope in Chile, the largest optical telescope in the world. The CSEM system adjusts a 2.5 m x 3 m elliptical mirror weighing 450 kg with nanometre accuracy to correct for atmospheric turbulence without being influenced by the telescope vibrations during the E-ELT star tracking motion. Based on the success of a full-size demonstrator design, ESO has commissioned the CSEM system for installation at the E-ELT.

At the high altitude Cerro Armazones site in Chile, the European Southern Observatory (ESO) is constructing the world’s largest optical ground-based telescope. This revolutionary new ground-based telescope, the European Extremely Large Telescope (E-ELT), will have a 39 metre diameter main mirror and will be the largest optical telescope in the world. It will gather 13 times more light than the largest optical telescopes operating today.

The telescope has an innovative mirror design that includes advanced adaptive optics to correct for atmospheric turbulence to give exceptional image quality. A sequence of secondary mirrors brings light from the primary 39 m mirror (M1) to the fifth mirror (M5) that performs the final image correction. M5 is an optically flat, elliptical mirror made from silicon carbide (SiC), 2.5 m x 3 m in size and weighing 450 kg.

The surface shape of the M5 mirror must be actively controlled down to resolutions corresponding to a few nanometers and without disturbing or being influenced by the telescope structure deformations and vibrations during the E-ELT star tracking motion.

Mirror Control System Design

CSEM was contracted by NTE (Spain) to design the opto-mechatronics and active control of the M5 mirror with the collaboration of SAGEM-REOSC (France) for the SiC mirror design, and CEDRAT Technologies (France) and PI Ceramic (Germany) for the piezo actuators.

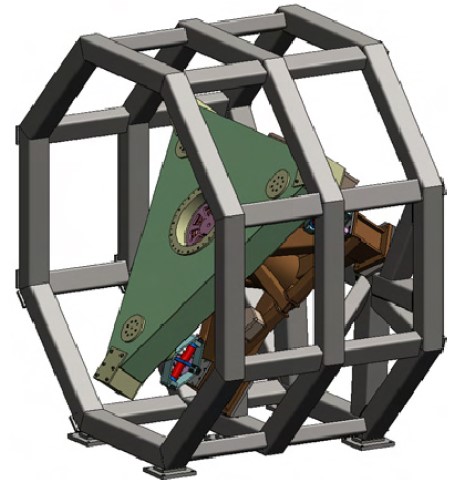

As the telescope orientation will change from zenith to horizontal during star tracking and observation, the M5 mirror is suspended by a central flexible membrane and three flexure rods linking it to three actuators.

The preliminary design indicated that a new concept of high load actuators would be required to actively support the massive SiC mirror in controlled tip and tilt motions over several arc-seconds with resolutions bellow the milli-arc seconds over seconds, up to above 10 Hz bandwidth.

Technology International Collaboration

CSEM proposed a control concept based on three actuators with 0.5 mm total stroke using the CEDRAT (FR) Technologies patented Amplified Piezo Actuator (APA) concept, each capable of withstanding >500 kg peak load. However, CEDRAT Technologies had never built such large systems before and an intense collaboration was organized by CSEM to successfully produce and test a prototype of a new APA-XXL-500 actuator using, as active parts, two of the largest piezo ceramic stacks available from PI CERAMIC (FR).

The complete system was fully modelled by CSEM using FEM tools (MSC NASTRAN and COMSOL), and the interaction of the control scheme was simulated in detail so as to prove that, in principle, the challenging demands of the E-ELT could be met.

A 5 metre high full-sized demonstrator design of the complete M5 opto-mechanical system was built by NTE (SP) with three APA-XXL-500 actuators to move and orient a dummy mirror load in three directions with the required nanometre positioning accuracy.

Based on the success of the CSEM demonstrator design, ESO has commissioned NTE to manufacture a system for installation at the E-ELT.

About CSEM

The CSEM is a private, non-profit Swiss research and technology organisation working as a national innovation accelerator—a catalyst for the transfer of technologies and know-how from fundamental research to industry. This role involves four principal tasks: to develop and maintain technology platforms; to integrate and combine technologies into workable systems; to mature those technologies until using them will add value to industrial clients; to support the process of transferring those technologies to industry.

CSEM works with all sizes of company and clients come from a wide range of industries around the world: medical, transportation, space, energy, security, manufacturing, life sciences, and telecommunications. Project requirements range from contract R&D, through small series production, to the development of specific business solutions.

CSEM has headquarters in Neuchâtel, Switzerland and centres in Muttenz, Zürich, Alpnach and Landquart.

Ivar Kielberg

Senior Project Manager

CSEM

Neuchâtel, Switzerland