Ampegon AG

2017

Ampegon AG delivers high voltage power supplies for heating ITER plasma gas

Fusion, the nuclear reaction that powers the sun and the stars, is a potential source of safe and virtually limitless energy. Harnessing fusion's power is the goal of the ITER project in France, which will be the key experimental step between today's fusion research machines and tomorrow's fusion power plants.

Ampegon AG has been contracted by Fusion for Energy (F4E), the organisation managing Europe’s contribution to ITER, to design, manufacture, install and commission the power supplies for the Electron Cyclotron Resonance Heating (ECRH) system, one of the plasma heating systems at ITER.

The modulator is a known difficult piece of equipment in other high energy physics based machines, because power, voltage, and current are unusually high. The ECRH modulators are clearly built with the experience accumulated within the accelerator based research facilities (CERN, E-XFEL) .

Ampegon power supplies are well-known for their modular design and high flexibility. With very high peak energy levels, accelerator and fusion facilities are dependent on a highly stable mains power supply and very low EMI figures. Ampegon technology keeps the mains consumption at a constant level and the system design results in low component stress and long component lifetime.

Power for fusion

The temperature inside the ITER fusion reactor needs to reach over 100 million ºC, almost ten times the temperature at the core of the sun. One of the heating systems that will be used to achieve the fusion reaction is the Electron Cyclotron system.

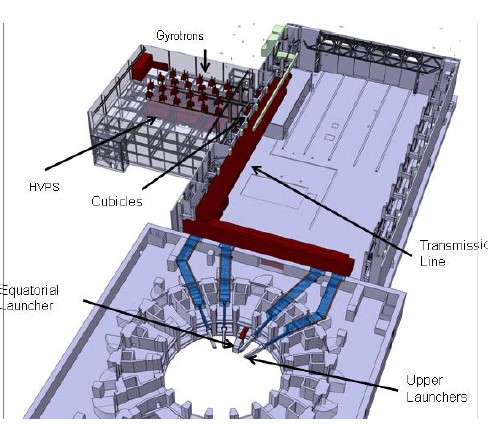

The main task of the Ampegon power supplies will be to transform mains electricity from the grid into the regulated pulsed current and voltage that ITER needs for generating the electromagnetic waves used in the Electron Cyclotron heating system.

The heating system will operate like a powerful microwave oven. High frequency electromagnetic waves will transfer their energy to the plasma, raise its temperature and drive additional current to sustain longer discharges. The precision of the Electron Cyclotron will help scientists to target specific plasma areas that require an extra blast of heat and maintain plasma confinement and stability.

Manufacture and installation

Ampegon is supplying 8 high voltage power supplies (55 kV/100 A) and 16 body power supplies (35 kV/100 mA) to ITER. A strict requirement of the power supply system is that it must be designed to shut down in less than 10 microseconds.

The ITER organisations have approved the design of the power supply systems and Ampegon has started manufacturing and testing the equipment at their Swiss factory. Installation and commissioning at the ITER site in Caderache, France will take place from 2019.

With very high peak energy levels, accelerator and fusion facilities are dependent on a highly stable mains power supply and very low EMI figures. Ampegon technology keeps the mains consumption at a constant level and the system design results in low component stress and long component lifetime.

About Ampegon AG

Ampegon AG serves the global science, medical, broadcast and industry markets with an extensive range of high voltage and RF electrical systems. The group develops RF amplifier systems, pulsed power technologies, high voltage and high current power supplies, short and long pulse modulators, for scientific, medical and industrial markets. The group is also a leading designer, manufacturer and system integrator of AM/DRM radio broadcast systems including transmitters, antennas and a wide range of auxiliary equipment. Ampegon group consists of Ampegon AG, Turgi (Switzerland), Ampegon Antenna Systems GmbH, Ludwigshafen (Germany) and Ampegon PPT GmbH, Dortmund (Germany) with a representation office in Beijing, China.

Josef Troxler

CEO

AMPEGON AG

Turgi, Switzerland

josef.troxler[@]ampegon.com

ampegon.com