VOLOTEK SA

2022

Volotek's Ultra High Vacuum Controllers back in action for the LHC 2022 restart

On March 22nd, 2022, at 08:00 precisely, following a three year shutdown, the LHC restarted. For the next four years its energy will be boosted from 6.5 TeV to 6.8 TeV per beam, enabling a new phase of experimentation. Remarkably, as for every restart, the vacuum controllers of Volotek SA, a Swiss electronics company based in Geneva, performed the critical task of verifying the quality of the vacuum level before any particle beam entered the tube. The Volotek controllers, part of the indispensable monitoring and vacuum engineering distributed all along the LHC ring, are instrumental in guaranteeing the proper circulation of the beam. Presently, the Bayard -Alpert gauge SVT 305 with the Volotek VGC1000 controller remain the baseline instruments for monitoring the LHC vacuum. This fundamental vacuum measurement technique, introduced by CERN for the ISR in the 1970s still serves all ultra high vacuum measurements at CERN. In these days of rapid obsolescence, the evolution of the Volotek product is remarkable.

The Volotek VGC1000 gauge vacuum controller and its associated SVT305 gauge are part of the vacuum monitoring chain of the LHC accelerator. They come into action to measure the ultra-high vacuum level beyond 10-9 mbar, only once the Penning and Pirani gauges have checked the vacuum level during pumpdown and bakeout. At this moment, the SVT hot ionization gauges are still switched off.

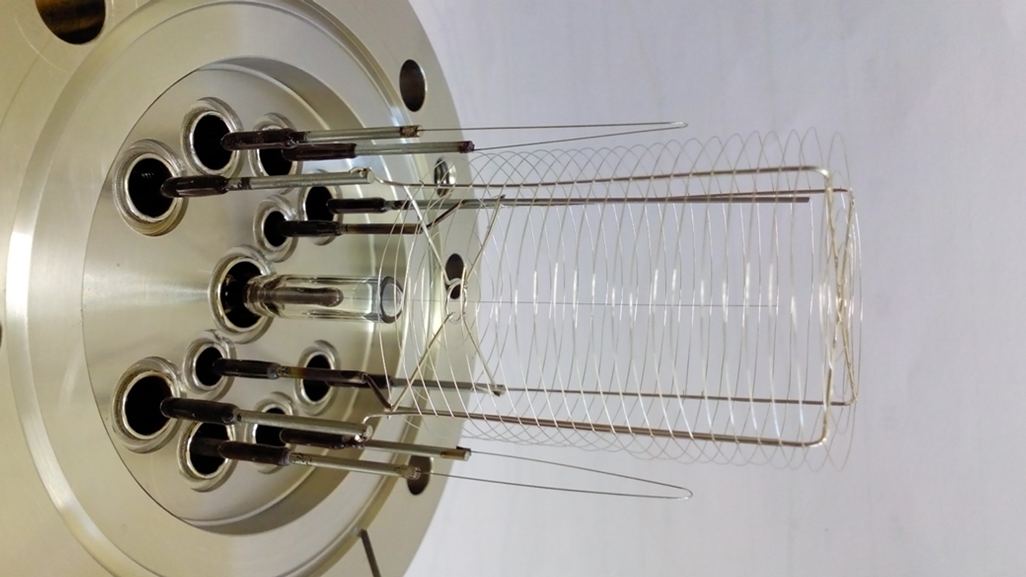

Based on the Bayard-Alpert principle, the SVT 305 is a hot-filament ionization gauge, which ionizes the gas molecules within its volume, amassing the ions on a thin collector wire. The resulting current to the ion collector determines the number of molecules present and indicates the pressure based on that measurement.

To measure the ion current, the Volotek VGC1000 deploys a low-noise integrated electrometer module with a sensitivity of 1 fA (femto Ampere) or 10-15 A. It offers scalability, reliability, and high stability in the extreme high-vacuum range of 10-11 mbar. The VCG1000 is a modular single channel 1/3 rack 3U high controller coming with a Profibus interface for external communications. The extraordinary performance of the Volotek controller lies in its low-noise signal architecture, which neutralizes electronic background interference, and avoids any current leaks thanks to rigorous differential OP Amp design and printed-circuit grounding techniques.

Due to the strong radiation, the gauges are housed up to 150 meters distant from the tunnel. To carry the low-level signal to the controller and to supply current to the gauges, this additional challenge is overcome using a radiation-insulated triaxial cable with double-layer shielding. A specific electronics topology in the receiving line carefully filters out the influence of the 50 Hz power supply incoming signal.Maintaining performance - the gauge’s evolution

Over time, the gauge design has been improved by implementing a unique modulated cathode-anode electron swing structure, to eliminate the secondary effect of generated photo-electrons adding to the pressure measurement. This re-design results in more filaments being connected. As fine as a spider’s web, the platinum-iridium alloy filament connections and their glass isolated feedthroughs are woven into an SVT gauge. For the replacement and repair of the gauges, CERN calls on the French company CVTM, based near Paris, which has the requisite expertise in high precision vacuum filament assembly and soldering.

CERN - the largest vacuum system worlwide

About VOLOTEK SA

Volotek SA is a Swiss company founded in 2002 in Geneva, specializing in scientific measurement instruments and low power electronics solutions. It benefits from the support of the InnoSuisse programme (agency for the promotion of innovation in Switzerland).

The company has extended its activities into sustainable energy solutions, in particular solar panels, where an elegant method to remove the deposit of dust by electrostatic means was developped. The solar technology was spun off to CleanFizz SA. During the COVID period, Volotek engineers developed a world first airborne virus detector that is now spun off to VoloSens SA. The company has currently five employees.

.

George McKarris

CEO

VOLOTEK SA

Satigny- Switzerland